- TOP

- TWD BV Holland

TWD BV Holland

TWD BV Holland (Temporary Works Design) is a Dutch venture

company founded in 2007.

One of the founders of the company, Mr. Kopper (concurrently GM of Barge Master), realized that there were few companies that could design and supply temporary structures and systems for offshore construction and installation works. He therefore founded TWD BV Holland as a company capable of custom designing and fabricating temporary facilities according to the customer's requirements.

Since then, TWD BV Holland has been successful in designing, procuring, and fabrication supervising for the equipment required for offshore wind projects, offshore civil projets, offshore oil and gas development projects, and decommissioning of offshore equipment, according to the requirements of our customers (installation contractors). TWD BV Holland has over 230 mechanical, structural, civil, electrical, instrument, and marine engineers who work closely with clients to find and design the best solutions.

TWD BV Holland has a proven track record of delivering the best solutions for offshore projects and has been involved in the design of Pile grippers, Pile upending systems, Lifting tools, Grillages for Monopiles, Transition pieces, Towers, Nacelles, Blades, and Jacket Template, etc. in more than 80% of recent large offshore wind projects. It is no exaggeration to say that TWD's designs have been utilized in most of offshore wind projects.

One of the founders of the company, Mr. Kopper (concurrently GM of Barge Master), realized that there were few companies that could design and supply temporary structures and systems for offshore construction and installation works. He therefore founded TWD BV Holland as a company capable of custom designing and fabricating temporary facilities according to the customer's requirements.

Since then, TWD BV Holland has been successful in designing, procuring, and fabrication supervising for the equipment required for offshore wind projects, offshore civil projets, offshore oil and gas development projects, and decommissioning of offshore equipment, according to the requirements of our customers (installation contractors). TWD BV Holland has over 230 mechanical, structural, civil, electrical, instrument, and marine engineers who work closely with clients to find and design the best solutions.

TWD BV Holland has a proven track record of delivering the best solutions for offshore projects and has been involved in the design of Pile grippers, Pile upending systems, Lifting tools, Grillages for Monopiles, Transition pieces, Towers, Nacelles, Blades, and Jacket Template, etc. in more than 80% of recent large offshore wind projects. It is no exaggeration to say that TWD's designs have been utilized in most of offshore wind projects.

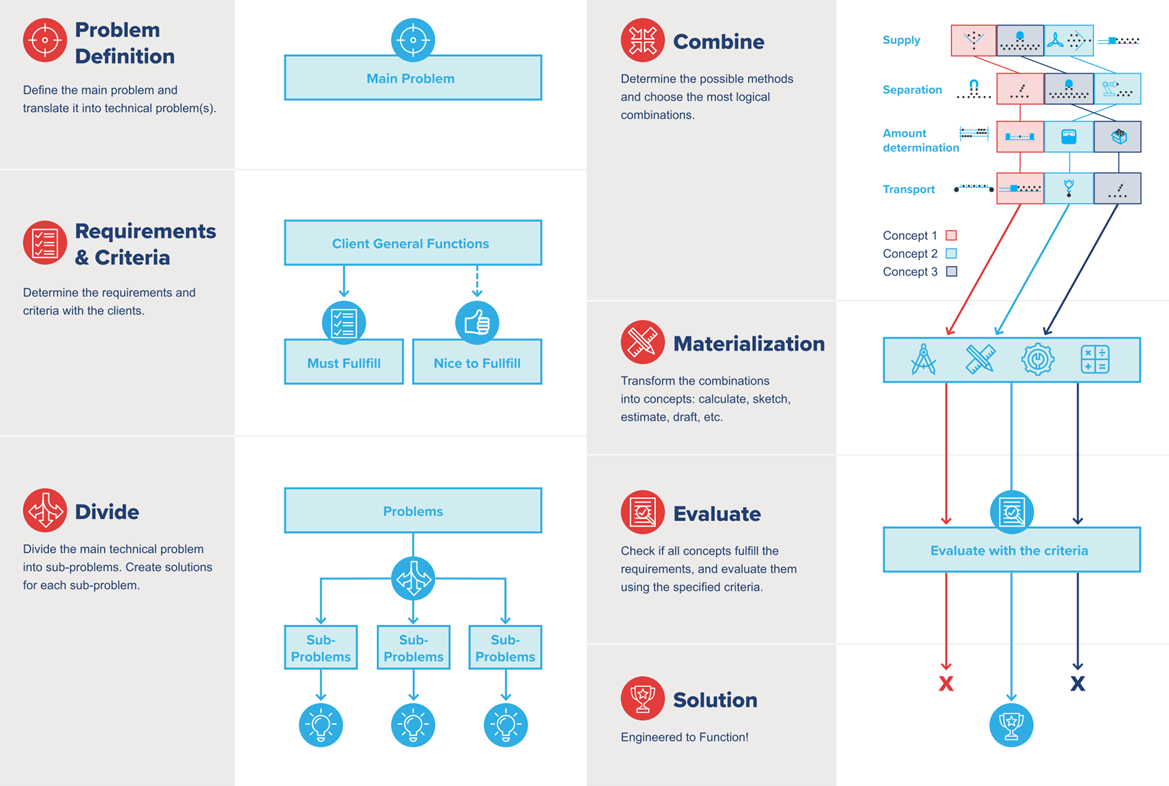

TWD BV Holland's design methodology is unique. First,

taking the customer's request and;

- (1) Identify the problems to be solved.

- (2) Listen to the customer's requirements and specifications in detail and discuss and define what the priorities are for the customer in solving the problems.

- (3) Break down the problems into several elements (elemental analysis). Then propose a solution for each element.

- (4) Propose a combination of each element and discuss and decide which combination is most appropriate for the customer (examination and decision on the optimal combination).

- (5) Analyze the optimal combination as a concept proposal, including strength and stability calculations, and drawings are made to estimate equipment costs.

- (6) Evaluate whether the proposed concept meets the customer's requirements.

- (7) If the evaluation is OK, the concept study is completed.

TWD's FUNCTIONAL DESIGN METHOD